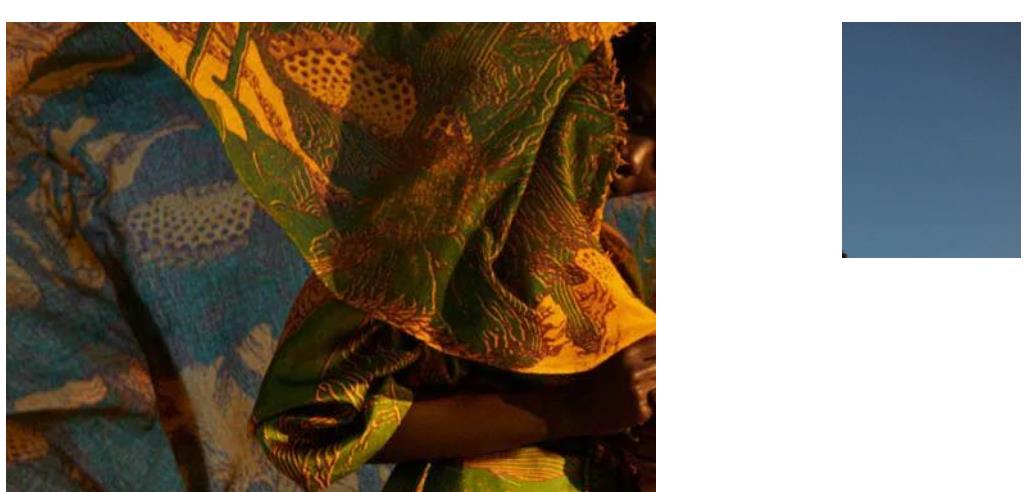

In recent years, high-value fabric printing using silk, imitation silk, wool, cotton, linen, polyester and other fabrics as carriers has emerged in an endless stream. Its pattern patterns are novel and diverse, with complex flower patterns and rich colors. It is widely used in high-end clothing, swimwear, neckties, headscarves and other clothing. How to meet the strict and high-quality special printing requirements has posed a new technical challenge to the digital printing process.

At present, the industry mostly adopts thermal sublimation transfer digital printing technology, which has three major pain points in the permeability of fabrics: "exposed white, flipped yarn, and positive contrast". The dye cannot fully enter the interior of the fabric, causing surface dyeing phenomenon and obvious color difference on the front and back sides. This is unacceptable for clothing brands with strict standards.

In response to the three major pain points, a few manufacturers in the industry have launched high penetration sublimation inks, which may be based on the use of dyes with poor sublimation fastness, combined with ordinary thermal sublimation dyes, to produce inks. Dyes with lower sublimation fastness enter the interior of the fabric during heating to solve the problem of penetration depth. This heat transfer printing+high permeability sublimation ink solution seems to solve the permeability problem, but sacrifices some printing quality and brings other extension problems:

1. Low light fastness

The common high elastic polyester fabric is mainly used outdoors, and sun exposure is an important indicator that brand merchants must consider. Some of the sublimation inks have a light fastness of only 2-3 levels, which falls far short of the sun fastness requirements of 5 levels or above for brands and foreign trade orders.

2. Presence of halo staining

The penetration direction of high permeability sublimation ink is uncontrollable, and migration and halo may occur during the color development process. In order to penetrate deeper, the image will become more blurry, greatly sacrificing the printing quality.

3. Poor resistance to migration

Due to the reduction of sublimation fastness, serious issues such as color matching can occur during transportation of printed products. Typically, it takes 1-2 months by sea, and the internal temperature of the container can reach 70-80 degrees Celsius. The sublimation ink can sublimate and contaminate adjacent products, resulting in a risk of chargeback.

“True penetration”

Coltex Launches CPT+Strong Penetration Printing Technology

In response to the current industry pain points and the high quality demand for high value fabrics from brand merchants, Coltex has launched a new generation of industrial grade digital direct jet printing masterpieces: CPT+strong penetration printing technology, combined with advanced IPC intelligent inkjet control technology, color intelligent color separation software, and strong penetration ink solution. This not only effectively solves the problem of insufficient penetration in digital printing of polyester high elasticity fabrics, but also improves the light fastness, color fastness, and migration resistance of printing, It enhances the saturation and contrast of printing colors, making the color transition smooth and delicate, achieving unparalleled printing effects and finished product quality, fully meeting the high-quality printing needs of brand merchants and foreign trade orders. It is a truly "true penetration" solution.

superior quality:

CPT+strong penetration printing technology not only solves the pain points of permeability such as "exposure, flipping, positive contrast", but also can match any printing process in terms of strong penetration, printing color, color fastness, light fastness, and thermal sublimation fastness, achieving a strong combination of strong penetration and high quality.

High precision non halo dyeing:

Coltex's advanced IPC intelligent inkjet control technology and color intelligent color separation software can ensure high clarity in front and back printing, and the penetration direction can be controlled according to demand, without migration and halo dyeing during the color process, maintaining the original printing accuracy. Regardless of the pattern pattern, high-precision printing quality can be achieved.

High stability:

CPT+strong penetration direct spray printing technology can achieve a sun fastness of 5 levels or above, improving the sublimation fastness level, avoiding serious problems such as color matching caused during transportation, ensuring high stability and consistency of printing quality throughout the entire printing process, and deeply matching the strict requirements of brand manufacturers and foreign trade orders.

From May 7th to 9th, at the "AME Clothing Intelligent Manufacturing Exhibition" at the Shanghai National Convention and Exhibition Center, Yili Technology cordially invites you to come to the booth to discuss strong penetration digital direct injection solutions and see how Coltex showcases the beauty of industrial printing.

Product and Printing Plan Preview

Snapdragon XT30

High penetration, high-speed, and intelligent digital direct jet printing machine

Fully suitable for high-temperature dispersion, activity

Coatings, Acidity, and Other Solutions

Unicorn S8000

Heat transfer digital printing machine

Yili Technology Booth Information

Exhibition time: May 7-9, 2023

Exhibition location: National Convention and Exhibition Center (Shanghai)

Booth number: 1.1H Hall 915

Since its establishment, Yili Technology has been committed to the application and innovation of industrial digital inkjet printing technology. With years of technical and industry development experience, it has ranked at the forefront of industrial digital inkjet printing core technology and provided reliable digital printing equipment and industry application solutions for many downstream customers.