Textile & Dye-Sublimation Printers-

GUV Printers-

Old model-

Xenons S8000 SERIES is a High-Speed sublimation printer that offers up to 640sq m/h print speed and quality at an affordable cost.

Ideal for dye-sublimation transfer printing of custom clothing, fashion apparel, sportswear, soft signage, merchandise, and hard surface work,it offers

Versatility Dye-Sublimation for widest application and maximum business.

This high-speed sublimation printing machine is the perfect solution for dye sublimation printing.

Ideal for dye-sublimation transfer printing of custom clothing, soft signage, merchandise, and hard surface work.

| Maximum output speed of 13320sqm/day (143375sq.ft/day) |

| With its staggered 15 EPSON i3200 printhead, Xenons Coltex CS15 model suitable for any work, combine a high speed 550sqm/h(5,918sq.ft/h) with high quality 2.5pl. That speed is higher previous EPSON printhead printers. |

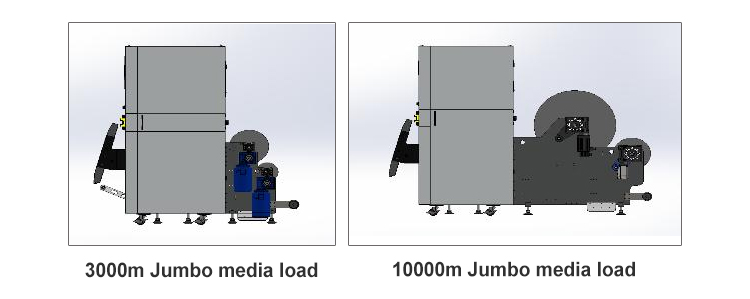

| Jumbo Roll media system |

| This media system support to load a jumbo roll transfer paper, Reduces the cost per square meter and shortens the downtime due to media replacement in comparison to smaller transfer paper rolls. |

| 10Kg auto ink supply system |

| An automation ink supply system enables you load 10kg inks per color, Reduce the running cost and the downtime due to ink replacement, The ink alarm system helps fill the ink in advance. |

| PC Station integrated to printer |

| Save the space for a computer desk, a PC station mounted on the printer. |

| An Easy-to-use system |

| Equipped with automatic capping and cleaning system, minimize the need to call an engineer. |

| Variable dots printing |

| Research has shown that the level of grayscale used in an image contribute considerably to its perceived quality, more so than pure dpi resolution. The larger dots enhanced a superior color, while the smallest dots providing gradation equivalent to a much higher resolution. |

| Efficient data algorithm reduce and correct banding |

| The special data algorithm enable the software analysis the data and reproduce the output method automatically minimizes ink drying times on substrates, and stepping error compensation, eliminating color banding effects. Depending on substrates and design, the o- ptimal percentage of feathering can achieve 20~80% speed increases avoiding the speed reductions caused by adding additional full passes |

| Intelligent Job management |

| Print meters setting, printing record management, color mapping function and ink calculation functions make sure an efficient job management. |

| S8000 series | |||

| Product model | S8-S-12H | S8-i-16H | |

| Print Head | Print head type | Epson S3200 A1 high-precision print head | Epson i3200 A1 high-precision print head |

| Number of print heads | 12 | 16 | |

| Permutations | 2×6 | 2*8 | |

| printing speed (According to the fabric and pattern, you can choose different schemes) |

4 colors | 300*600dpi(1pass)680㎡/h | 720*600dpi(1pass)580㎡/h |

| 300*1200dpi(2pass)350㎡/h | 720*1200dpi(2pass)290㎡/h | ||

| 6 colors | 300*600dpi(1pass)680㎡/h | / | |

| 300*1200dpi(2pass)350㎡/h | / | ||

| 8 colors | / | 720*1200dpi(2pass)290㎡/h | |

| / | 720*1200dpi(3pass)193㎡/h | ||

| Print media | Maximum print width | 2000mm | |

| Available material width | 2050mm | ||

| material medium | Sublimation paper, titanium dioxide paper, wallpaper, film | ||

| Available material weight | Minimum 22-110g/㎡ | ||

| material thickness | 2-50 silk | ||

| Ink System | ink type | Dye sublimation ink, pigment ink | |

| ink color | C, M, Y, K, optional LM, LC, LK, LLK | ||

| ink volume | 10L/color | ||

| Ink supply | Automatic ink supply and automatic negative pressure system | ||

| Software system | Production Software | Optional self-developed software YIPS, TexPrint, NeoStampa, etc. | |

| image type | File format TIFF/JPG/EPS/PDF, color mode RGB/CMYK | ||

| Function configuration | Platform Support System | tower structure support | |

| Print platform | Honeycomb uniform suction printing platform 3.0 | ||

| Maglev drive system | Japanese original THK high-quiet dual guide rails, magnetic levitation motor, and magnetic grid system | ||

| print head protection system | Triple Protect System | ||

| Fully automatic cleaning and moisturizing all-in-one component | Fully automatic cleaning and moisturizing all-in-one component | ||

| Pressure roller: rubber roller φ160mm/220mm (cylinder) | |||

| Unloading: MAX can be placed Φ1000mm | |||

| Tension rubber roller conveying system | Receiving: MAX can be collected Φ450mm | ||

| Heating system | Infrared hot air circulation double layer heating | ||

| Work environment | power supply | 380VAC±5%, three-phase five-wire/220VC, 50/60HZ | |

| Power | Main machine 6KW, drying 10KW | ||

| Supply air flow | 0.5~0.7Mpa, 0.15m³/hr (dry, oil-free and water-free) | ||

| temperature and humidity | Ambient room temperature: recommended temperature 15-30°C, ambient humidity: recommended 50%-80% (non-condensing) | ||

| Product Specifications | size | 4100*2400*1850 length*width*height (mm), including 10,000-meter rolling device | |

| weight | About 1500KG | ||